Anchor plates are prepared according to the dimensions specified in the application projects. Anchor plates are fixing to the reinforcement and concrete is poured so that it remains in the concrete. If pouring of concrete was done before installitaion, anchor plates fix on concrete with chemical injection.

Connecting of spheres and pipes is made by specialist personnel on floor or air. The part connected onto floor is lifted up with the help of crane.

All stages of the assembly process are carried out by expert personnel in accordance with the standards. After the assembly process is completed, the controls are made and as the last step, the support welds are made and project complete.

It is the distribution of the load transfer mechanism in such a way that there is primarily axial tension or compression.

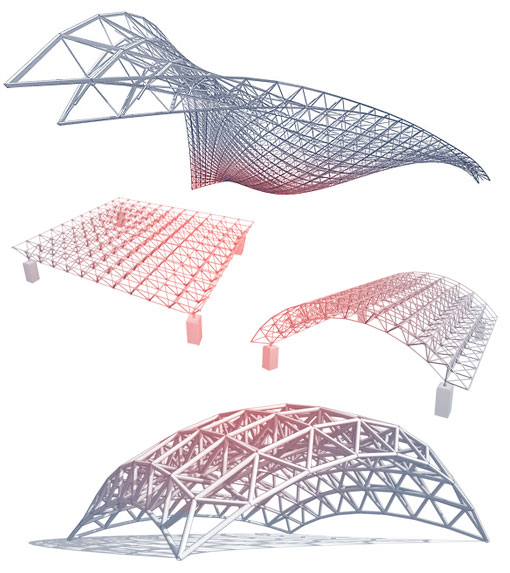

Space frame systems can allow very large span to be built because of they are modular and leight systems.